About Us

Our Philosophy

At Artura, our designers and engineers strive to find engineered solutions in a creative and thoughtful way.

Our design philosophy is to add value to our clients’ projects through engineered optimisation and applying our palette of experience.

We help guide a project into an engineered, buildable, and economical solution. Every structure is unique, bespoke and requires interfacing with its location.

Communication, collaboration, and co-ordination form the backbone of most projects. Our aim is to facilitate and encourage this way of working.

Teamwork, Collaboration and BIM

Apart from our internal teamwork, most of a project’s decision-making is done with a collaborating design team and working and communicating with other specialists.

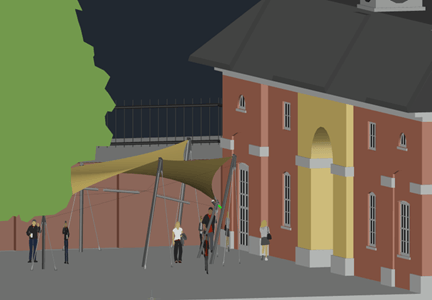

We work with many clients in the international membrane contracting industry. From an early stage of a project, we undertake scheme design with structural analysis, detailed engineering and demonstrate results using 3D-conceptualisation.

When a scheme is resolved we offer the execution of detail design up to fabrication and installation. Innovation and membrane technological developments feed our design process so that we can furnish each project with the latest materials and ideas.

We are accustomed to working exclusively in the 3D modelled environment, a precedent for building projects with BIM document management and task-team collaboration.

Schemes and Feasibility studies

It has been seen many times that it pays to involve a

consultancy at the earliest stages of a tensile membrane design.

Software-based analysis tools allow rapid, economical evaluation of concepts at an early stage for further development.

Tender documentation

Artura provide bespoke full tender packages for membranes and steelwork for costing at eg. RIBA Stages 3 and 4.

Preliminary or full structure design to client requirements can be developed to any level of detail prior to tender, eg. Design & Build projects.

Ignoring the boundaries of a comfort zone

Over the years our work has led us into many fascinating areas of bespoke design, and not solely our specialisation of architectural tensile membranes.

We enjoy working with clients and partners who accompany the design process and who place value on a culture of exploring new ideas.

Benedict Whybrow

Benedict studied Mechanical Engineering with German at Bath University before embarking on a multi-faceted career path.

His fascination with mechanical movement had already developed into making kinetic sculpture in a group studio on Bristol’s dockside. Benedict exhibited his work in exhibitions and installations across the UK and in Germany and was one of the drivers in securing a new permanent home for the ‘ARTSPACE’ artists. These activities were supplemented with the teaching of screen-printing, designing and building pneumatic advertising structures and playground equipment.

Later there came work as assistant director on a documentary about the extensions to the Holy Prophet’s mosques in Saudi Arabia. This led to encounters with Frei Otto and other working engineers and architects in the membrane industry.

His interest in tensile fabric membranes has since been developed professionally over 20 years through work as a designer, project manager, design coordinator and consultant to this industry.

Outside of work, Benedict has two almost grown-up children, is a keen dinghy sailor and avid miniature modeller.

Ivan Teed

Ivan studied Mechanical Engineering at Nottingham University before starting his career in the tensile membrane industry at Landrell Fabric Engineering as a design technician.

After a couple of years with Landrell, Architen & then Architen Landrell learning the design aspects of tensile fabric structures, he moved to THD where he progressed his knowledge to become a structural engineer experienced in the analysis and engineering of tensile membrane structures, cable nets and other architectural structures.

Outside of work, Ivan has three young boys to keep track of, is a keen runner and in his youth represented Wales and Great Britain at Orienteering.

Paul Sidebotham

After school Paul studied horology for a year with the BHI in Birmingham jewellery quarter where he learned draughting and metalworking for clock and watch making.

Then he moved to work on larger and more complicated mechanical equipment at Harper Adams University where innovation in agricultural equipment fired his imagination in design and taught him the engineering and CAD skills he

still uses every working day.

His career path traversed design and management for manufacturing agricultural equipment and steel framed buildings and then on to design and project management of architectural structures – working primarily with metal, timber and

tensile fabric.

Paul lives near Truro with his family, enjoying Cornwall, song writing and the occasional performance.

- Wimbledon Centre Court retractable roof,

- Sharm el Sheikh Airport (Egypt),

- Lords Mound Stand refurbishment,

- Aintree Racecourse main stand,

- Heathrow T5 main car park canopies,

- Scotstoun Stadium (Glasgow)